超硬ドリル

ドリーマー φ3.0シャンク (コーティング)

CDRP○.○○-10D

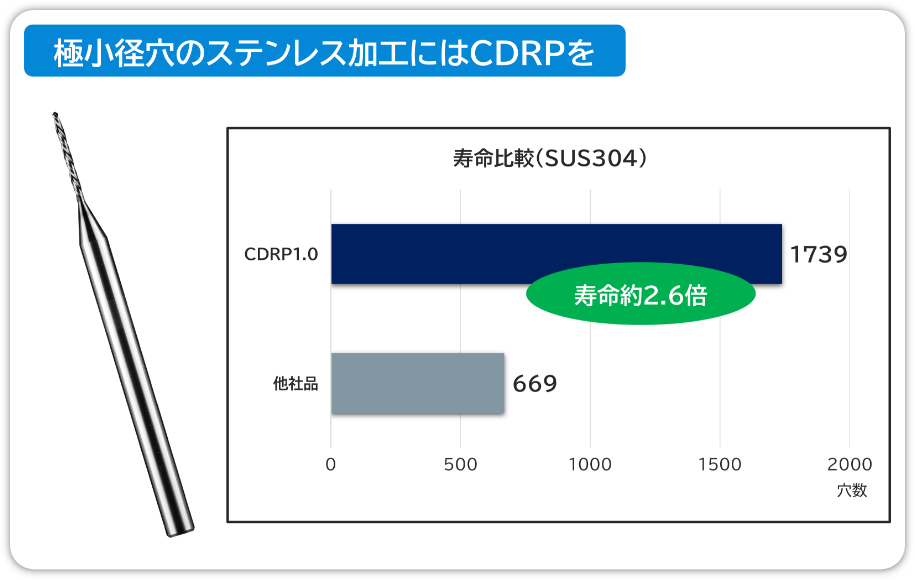

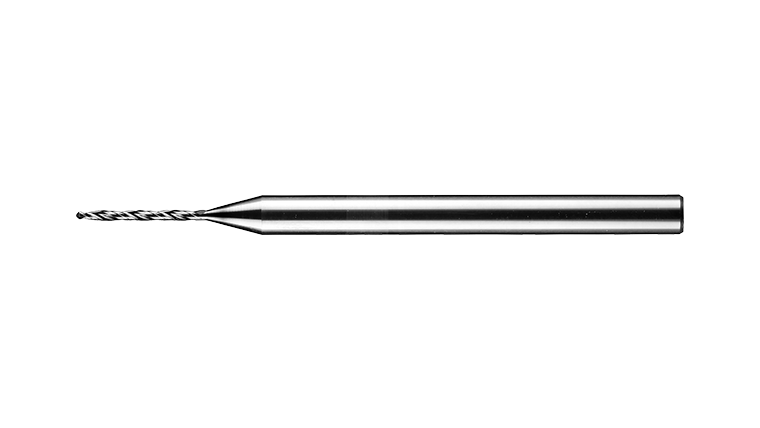

- 超薄膜 Purple Coating を施すことで、SUS 加工に抜群の効果を発揮。ノンコート比2倍以上の高寿命!

- コーテイングタイプでも刃径公差0/-0.003を維持。

- シャンク径Φ3.0に対し、h4公差(0/-0.003)を採用する事で、振れ精度と穴位置精度を更に追及。

- 丹念に研究を重ねた工具形状を採用。切りくず排出性能が大幅に向上し、耐久性に優れる。

- 有効加工長を10Dに設定。刃径の10倍まで加工可能。

本製品の加工事例

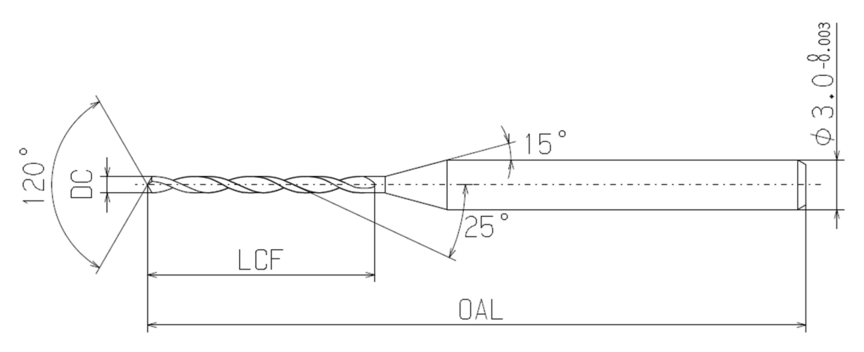

寸法表

| 型式・刃径DC | 有効長LU | 溝長LCF | 全長OAL | シャンク径DCON |

|---|---|---|---|---|

| CDRP 0.10 | 1.0 | 1.2 | 40 | 3.0 |

| CDRP 0.11 | 1.1 | 1.32 | 40 | 3.0 |

| CDRP 0.12 | 1.2 | 1.44 | 40 | 3.0 |

| CDRP 0.13 | 1.3 | 1.56 | 40 | 3.0 |

| CDRP 0.14 | 1.4 | 1.68 | 40 | 3.0 |

| CDRP 0.15 | 1.5 | 1.8 | 40 | 3.0 |

| CDRP 0.16 | 1.6 | 1.92 | 40 | 3.0 |

| CDRP 0.17 | 1.7 | 2.04 | 40 | 3.0 |

| CDRP 0.18 | 1.8 | 2.16 | 40 | 3.0 |

| CDRP 0.19 | 1.9 | 2.28 | 40 | 3.0 |

| CDRP 0.20 | 2.0 | 2.4 | 40 | 3.0 |

| CDRP 0.21 | 2.1 | 2.52 | 40 | 3.0 |

| CDRP 0.22 | 2.2 | 2.64 | 40 | 3.0 |

| CDRP 0.23 | 2.3 | 2.76 | 40 | 3.0 |

| CDRP 0.24 | 2.4 | 2.88 | 40 | 3.0 |

| CDRP 0.25 | 2.5 | 3.0 | 40 | 3.0 |

| CDRP 0.26 | 2.6 | 3.12 | 40 | 3.0 |

| CDRP 0.27 | 2.7 | 3.24 | 40 | 3.0 |

| CDRP 0.28 | 2.8 | 3.36 | 40 | 3.0 |

| CDRP 0.29 | 2.9 | 3.48 | 40 | 3.0 |

| CDRP 0.30 | 3.0 | 3.6 | 45 | 3.0 |

| CDRP 0.31 | 3.1 | 3.72 | 45 | 3.0 |

| CDRP 0.32 | 3.2 | 3.84 | 45 | 3.0 |

| CDRP 0.33 | 3.3 | 3.96 | 45 | 3.0 |

| CDRP 0.34 | 3.4 | 4.08 | 45 | 3.0 |

| CDRP 0.35 | 3.5 | 4.2 | 45 | 3.0 |

| CDRP 0.36 | 3.6 | 4.32 | 45 | 3.0 |

| CDRP 0.37 | 3.7 | 4.44 | 45 | 3.0 |

| CDRP 0.38 | 3.8 | 4.56 | 45 | 3.0 |

| CDRP 0.39 | 3.9 | 4.68 | 45 | 3.0 |

| CDRP 0.40 | 4.0 | 4.8 | 45 | 3.0 |

| CDRP 0.41 | 4.1 | 4.92 | 45 | 3.0 |

| CDRP 0.42 | 4.2 | 5.04 | 45 | 3.0 |

| CDRP 0.43 | 4.3 | 5.16 | 45 | 3.0 |

| CDRP 0.44 | 4.4 | 5.28 | 45 | 3.0 |

| CDRP 0.45 | 4.5 | 5.4 | 45 | 3.0 |

| CDRP 0.46 | 4.6 | 5.52 | 45 | 3.0 |

| CDRP 0.47 | 4.7 | 5.64 | 45 | 3.0 |

| CDRP 0.48 | 4.8 | 5.76 | 45 | 3.0 |

| CDRP 0.49 | 4.9 | 5.88 | 45 | 3.0 |

| CDRP 0.50 | 5.0 | 6.0 | 45 | 3.0 |

| CDRP 0.51 | 5.1 | 6.12 | 45 | 3.0 |

| CDRP 0.52 | 5.2 | 6.24 | 45 | 3.0 |

| CDRP 0.53 | 5.3 | 6.36 | 45 | 3.0 |

| CDRP 0.54 | 5.4 | 6.48 | 45 | 3.0 |

| CDRP 0.55 | 5.5 | 6.6 | 45 | 3.0 |

| CDRP 0.56 | 5.6 | 6.72 | 45 | 3.0 |

| CDRP 0.57 | 5.7 | 6.84 | 45 | 3.0 |

| CDRP 0.58 | 5.8 | 6.96 | 45 | 3.0 |

| CDRP 0.59 | 5.9 | 7.08 | 45 | 3.0 |

| CDRP 0.60 | 6.0 | 7.2 | 45 | 3.0 |

| CDRP 0.61 | 6.1 | 7.32 | 45 | 3.0 |

| CDRP 0.62 | 6.2 | 7.44 | 45 | 3.0 |

| CDRP 0.63 | 6.3 | 7.56 | 45 | 3.0 |

| CDRP 0.64 | 6.4 | 7.68 | 45 | 3.0 |

| CDRP 0.65 | 6.5 | 7.8 | 45 | 3.0 |

| CDRP 0.66 | 6.6 | 7.92 | 45 | 3.0 |

| CDRP 0.67 | 6.7 | 8.04 | 45 | 3.0 |

| CDRP 0.68 | 6.8 | 8.16 | 45 | 3.0 |

| CDRP 0.69 | 6.9 | 8.28 | 45 | 3.0 |

| CDRP 0.70 | 7.0 | 8.4 | 45 | 3.0 |

| CDRP 0.71 | 7.1 | 8.52 | 45 | 3.0 |

| CDRP 0.72 | 7.2 | 8.64 | 45 | 3.0 |

| CDRP 0.73 | 7.3 | 8.76 | 45 | 3.0 |

| CDRP 0.74 | 7.4 | 8.88 | 45 | 3.0 |

| CDRP 0.75 | 7.5 | 9.0 | 45 | 3.0 |

| CDRP 0.76 | 7.6 | 9.12 | 45 | 3.0 |

| CDRP 0.77 | 7.7 | 9.24 | 45 | 3.0 |

| CDRP 0.78 | 7.8 | 9.36 | 45 | 3.0 |

| CDRP 0.79 | 7.9 | 9.48 | 45 | 3.0 |

| CDRP 0.80 | 8.0 | 9.6 | 45 | 3.0 |

| CDRP 0.81 | 8.1 | 9.72 | 45 | 3.0 |

| CDRP 0.82 | 8.2 | 9.84 | 45 | 3.0 |

| CDRP 0.83 | 8.3 | 9.96 | 45 | 3.0 |

| CDRP 0.84 | 8.4 | 10.08 | 45 | 3.0 |

| CDRP 0.85 | 8.5 | 10.2 | 45 | 3.0 |

| CDRP 0.86 | 8.6 | 10.32 | 45 | 3.0 |

| CDRP 0.87 | 8.7 | 10.44 | 45 | 3.0 |

| CDRP 0.88 | 8.8 | 10.56 | 45 | 3.0 |

| CDRP 0.89 | 8.9 | 10.68 | 45 | 3.0 |

| CDRP 0.90 | 9.0 | 10.8 | 45 | 3.0 |

| CDRP 0.91 | 9.1 | 10.92 | 45 | 3.0 |

| CDRP 0.92 | 9.2 | 11.04 | 45 | 3.0 |

| CDRP 0.93 | 9.3 | 11.16 | 45 | 3.0 |

| CDRP 0.94 | 9.4 | 11.28 | 45 | 3.0 |

| CDRP 0.95 | 9.5 | 11.4 | 45 | 3.0 |

| CDRP 0.96 | 9.6 | 11.52 | 45 | 3.0 |

| CDRP 0.97 | 9.7 | 11.64 | 45 | 3.0 |

| CDRP 0.98 | 9.8 | 11.76 | 45 | 3.0 |

| CDRP 0.99 | 9.9 | 11.88 | 45 | 3.0 |

| CDRP 1.00 | 10.0 | 12.0 | 45 | 3.0 |

参考切削条件

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 19100 | 0.002 | 0.1~0.2D |

| 0.2 | 17500 | 0.005 | 0.1~0.2D |

| 0.3 | 15900 | 0.010 | 0.1~0.2D |

| 0.4 | 15100 | 0.015 | 0.1~0.2D |

| 0.5 | 14600 | 0.020 | 0.2~0.3D |

| 0.6 | 13300 | 0.025 | 0.2~0.3D |

| 0.7 | 12300 | 0.030 | 0.2~0.3D |

| 0.8 | 11500 | 0.035 | 0.2~0.3D |

| 0.9 | 11000 | 0.040 | 0.2~0.3D |

| 1.0 | 10500 | 0.045 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 19100 | 0.001 | 0.1~0.2D |

| 0.2 | 17500 | 0.004 | 0.1~0.2D |

| 0.3 | 15900 | 0.006 | 0.1~0.2D |

| 0.4 | 15100 | 0.008 | 0.1~0.2D |

| 0.5 | 14600 | 0.010 | 0.2~0.3D |

| 0.6 | 13300 | 0.012 | 0.2~0.3D |

| 0.7 | 12300 | 0.014 | 0.2~0.3D |

| 0.8 | 11500 | 0.016 | 0.2~0.3D |

| 0.9 | 11000 | 0.018 | 0.2~0.3D |

| 1.0 | 10500 | 0.020 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 15900 | 0.001 | 0.1~0.2D |

| 0.2 | 12700 | 0.002 | 0.1~0.2D |

| 0.3 | 10600 | 0.003 | 0.1~0.2D |

| 0.4 | 9600 | 0.004 | 0.1~0.2D |

| 0.5 | 8300 | 0.005 | 0.2~0.3D |

| 0.6 | 6900 | 0.006 | 0.2~0.3D |

| 0.7 | 6400 | 0.007 | 0.2~0.3D |

| 0.8 | 5600 | 0.008 | 0.2~0.3D |

| 0.9 | 5300 | 0.009 | 0.2~0.3D |

| 1.0 | 4800 | 0.010 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 19100 | 0.001 | 0.1~0.2D |

| 0.2 | 17500 | 0.004 | 0.1~0.2D |

| 0.3 | 15900 | 0.006 | 0.1~0.2D |

| 0.4 | 15100 | 0.008 | 0.1~0.2D |

| 0.5 | 14600 | 0.010 | 0.2~0.3D |

| 0.6 | 13300 | 0.012 | 0.2~0.3D |

| 0.7 | 12300 | 0.014 | 0.2~0.3D |

| 0.8 | 11500 | 0.016 | 0.2~0.3D |

| 0.9 | 11000 | 0.018 | 0.2~0.3D |

| 1.0 | 10500 | 0.020 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 20700 | 0.005 | 0.1~0.2D |

| 0.2 | 19100 | 0.010 | 0.1~0.2D |

| 0.3 | 17000 | 0.020 | 0.1~0.2D |

| 0.4 | 15900 | 0.030 | 0.1~0.2D |

| 0.5 | 15300 | 0.035 | 0.2~0.3D |

| 0.6 | 14900 | 0.040 | 0.2~0.3D |

| 0.7 | 14600 | 0.045 | 0.2~0.3D |

| 0.8 | 14300 | 0.050 | 0.2~0.3D |

| 0.9 | 13400 | 0.055 | 0.2~0.3D |

| 1.0 | 12700 | 0.060 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 17500 | 0.004 | 0.1~0.2D |

| 0.2 | 15900 | 0.005 | 0.1~0.2D |

| 0.3 | 14900 | 0.010 | 0.1~0.2D |

| 0.4 | 14300 | 0.015 | 0.1~0.2D |

| 0.5 | 13400 | 0.020 | 0.2~0.3D |

| 0.6 | 12200 | 0.025 | 0.2~0.3D |

| 0.7 | 11400 | 0.030 | 0.2~0.3D |

| 0.8 | 10700 | 0.035 | 0.2~0.3D |

| 0.9 | 10300 | 0.040 | 0.2~0.3D |

| 1.0 | 9900 | 0.045 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 17500 | 0.001 | 0.1~0.2D |

| 0.2 | 15900 | 0.002 | 0.1~0.2D |

| 0.3 | 13800 | 0.003 | 0.1~0.2D |

| 0.4 | 12700 | 0.004 | 0.1~0.2D |

| 0.5 | 11500 | 0.005 | 0.2~0.3D |

| 0.6 | 10600 | 0.006 | 0.2~0.3D |

| 0.7 | 10000 | 0.007 | 0.2~0.3D |

| 0.8 | 9600 | 0.008 | 0.2~0.3D |

| 0.9 | 9200 | 0.009 | 0.2~0.3D |

| 1.0 | 8900 | 0.010 | 0.2~0.3D |

| 刃径DC(mm) | 回転数n(min-1) | 送り量f(mm/rev) | ステップ量 |

|---|---|---|---|

| 0.1 | 20700 | 0.005 | 0.1~0.2D |

| 0.2 | 19100 | 0.010 | 0.1~0.2D |

| 0.3 | 17000 | 0.015 | 0.1~0.2D |

| 0.4 | 15900 | 0.020 | 0.1~0.2D |

| 0.5 | 15300 | 0.025 | 0.2~0.3D |

| 0.6 | 14900 | 0.030 | 0.2~0.3D |

| 0.7 | 14600 | 0.035 | 0.2~0.3D |

| 0.8 | 14300 | 0.040 | 0.2~0.3D |

| 0.9 | 13400 | 0.045 | 0.2~0.3D |

| 1.0 | 12700 | 0.050 | 0.2~0.3D |