-

ホーム

-

製品一覧

-

超硬リーマ Cシリーズ

超硬リーマ

超硬リーマ Cシリーズ

CC○.○○○

寸法表

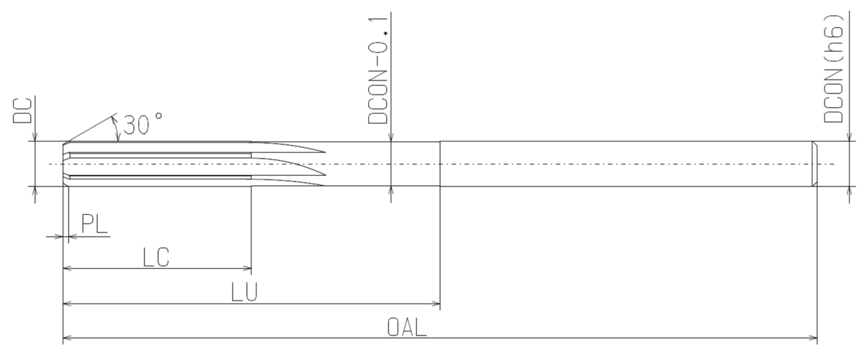

| 型式・刃径DC |

食付き長PL |

刃長LC |

首下長LU |

全長OAL |

シャンク径DCON |

刃数ZEFP |

| CC 2.910~3.005 |

0.5 |

20 |

40 |

80 |

2.9 |

4 |

| CC 3.010~3.105 |

0.5 |

20 |

40 |

80 |

3.0 |

4 |

| CC 3.110~3.205 |

0.5 |

20 |

40 |

80 |

3.1 |

4 |

| CC 3.210~3.305 |

0.5 |

20 |

40 |

80 |

3.2 |

4 |

| CC 3.310~3.405 |

0.5 |

20 |

40 |

80 |

3.3 |

4 |

| CC 3.410~3.505 |

0.5 |

20 |

40 |

80 |

3.4 |

4 |

| CC 3.510~3.605 |

0.5 |

20 |

40 |

80 |

3.5 |

4 |

| CC 3.610~3.705 |

0.5 |

20 |

40 |

80 |

3.6 |

4 |

| CC 3.710~3.805 |

0.5 |

20 |

40 |

80 |

3.7 |

4 |

| CC 3.810~3.905 |

0.5 |

20 |

40 |

80 |

3.8 |

4 |

| CC 3.910~4.005 |

0.5 |

20 |

40 |

80 |

3.9 |

4 |

| CC 4.010~4.105 |

0.5 |

20 |

40 |

80 |

4.0 |

6 |

| CC 4.110~4.205 |

0.5 |

20 |

40 |

80 |

4.1 |

6 |

| CC 4.210~4.305 |

0.5 |

20 |

40 |

80 |

4.2 |

6 |

| CC 4.310~4.405 |

0.5 |

20 |

40 |

80 |

4.3 |

6 |

| CC 4.410~4.505 |

0.5 |

20 |

40 |

80 |

4.4 |

6 |

| CC 4.510~4.605 |

0.5 |

20 |

40 |

80 |

4.5 |

6 |

| CC 4.610~4.705 |

0.5 |

20 |

40 |

80 |

4.6 |

6 |

| CC 4.710~4.805 |

0.5 |

20 |

40 |

80 |

4.7 |

6 |

| CC 4.810~4.905 |

0.5 |

20 |

40 |

80 |

4.8 |

6 |

| CC 4.910~5.005 |

0.5 |

20 |

40 |

80 |

4.9 |

6 |

| CC 5.010~5.105 |

0.8 |

25 |

50 |

100 |

5.0 |

6 |

| CC 5.110~5.205 |

0.8 |

25 |

50 |

100 |

5.1 |

6 |

| CC 5.210~5.305 |

0.8 |

25 |

50 |

100 |

5.2 |

6 |

| CC 5.310~5.405 |

0.8 |

25 |

50 |

100 |

5.3 |

6 |

| CC 5.410~5.505 |

0.8 |

25 |

50 |

100 |

5.4 |

6 |

| CC 5.510~5.605 |

0.8 |

25 |

50 |

100 |

5.5 |

6 |

| CC 5.610~5.705 |

0.8 |

25 |

50 |

100 |

5.6 |

6 |

| CC 5.710~5.805 |

0.8 |

25 |

50 |

100 |

5.7 |

6 |

| CC 5.810~5.905 |

0.8 |

25 |

50 |

100 |

5.8 |

6 |

| CC 5.910~6.005 |

0.8 |

25 |

50 |

100 |

5.9 |

6 |

| CC 6.010~6.105 |

0.8 |

25 |

50 |

100 |

6.0 |

6 |

| CC 6.110~6.205 |

0.8 |

25 |

50 |

100 |

6.1 |

6 |

| CC 6.210~6.305 |

0.8 |

25 |

50 |

100 |

6.2 |

6 |

| CC 6.310~6.405 |

0.8 |

25 |

50 |

100 |

6.3 |

6 |

| CC 6.410~6.505 |

0.8 |

25 |

50 |

100 |

6.4 |

6 |

| CC 6.510~6.605 |

0.8 |

25 |

50 |

100 |

6.5 |

6 |

| CC 6.610~6.705 |

0.8 |

25 |

50 |

100 |

6.6 |

6 |

| CC 6.710~6.805 |

0.8 |

25 |

50 |

100 |

6.7 |

6 |

| CC 6.810~6.905 |

0.8 |

25 |

50 |

100 |

6.8 |

6 |

| CC 6.910~7.005 |

0.8 |

25 |

50 |

100 |

6.9 |

6 |

| CC 7.010~7.105 |

0.8 |

25 |

50 |

100 |

7.0 |

6 |

| CC 7.110~7.205 |

0.8 |

25 |

50 |

100 |

7.1 |

6 |

| CC 7.210~7.305 |

0.8 |

25 |

50 |

100 |

7.2 |

6 |

| CC 7.310~7.405 |

0.8 |

25 |

50 |

100 |

7.3 |

6 |

| CC 7.410~7.505 |

0.8 |

25 |

50 |

100 |

7.4 |

6 |

| CC 7.510~7.605 |

0.8 |

25 |

50 |

100 |

7.5 |

6 |

| CC 7.610~7.705 |

0.8 |

25 |

50 |

100 |

7.6 |

6 |

| CC 7.710~7.805 |

0.8 |

25 |

50 |

100 |

7.7 |

6 |

| CC 7.810~7.905 |

0.8 |

25 |

50 |

100 |

7.8 |

6 |

| CC 7.910~8.005 |

0.8 |

25 |

50 |

100 |

7.9 |

6 |

| CC 8.010~8.105 |

1.0 |

25 |

60 |

115 |

8.0 |

6 |

| CC 8.110~8.205 |

1.0 |

25 |

60 |

115 |

8.1 |

6 |

| CC 8.210~8.305 |

1.0 |

25 |

60 |

115 |

8.2 |

6 |

| CC 8.310~8.405 |

1.0 |

25 |

60 |

115 |

8.3 |

6 |

| CC 8.410~8.505 |

1.0 |

25 |

60 |

115 |

8.4 |

6 |

| CC 8.510~8.605 |

1.0 |

25 |

60 |

115 |

8.5 |

6 |

| CC 8.610~8.705 |

1.0 |

25 |

60 |

115 |

8.6 |

6 |

| CC 8.710~8.805 |

1.0 |

25 |

60 |

115 |

8.7 |

6 |

| CC 8.810~8.905 |

1.0 |

25 |

60 |

115 |

8.8 |

6 |

| CC 8.910~9.005 |

1.0 |

25 |

60 |

115 |

8.9 |

6 |

| CC 9.010~9.105 |

1.0 |

25 |

60 |

115 |

9.0 |

6 |

| CC 9.110~9.205 |

1.0 |

25 |

60 |

115 |

9.1 |

6 |

| CC 9.210~9.305 |

1.0 |

25 |

60 |

115 |

9.2 |

6 |

| CC 9.310~9.405 |

1.0 |

25 |

60 |

115 |

9.3 |

6 |

| CC 9.410~9.505 |

1.0 |

25 |

60 |

115 |

9.4 |

6 |

| CC 9.510~9.605 |

1.0 |

25 |

60 |

115 |

9.5 |

6 |

| CC 9.610~9.705 |

1.0 |

25 |

60 |

115 |

9.6 |

6 |

| CC 9.710~9.805 |

1.0 |

25 |

60 |

115 |

9.7 |

6 |

| CC 9.810~9.905 |

1.0 |

25 |

60 |

115 |

9.8 |

6 |

| CC 9.910~10.005 |

1.0 |

25 |

60 |

115 |

9.9 |

6 |

| CC 10.010~10.105 |

1.0 |

25 |

60 |

115 |

10.0 |

6 |

| CC 10.110~10.205 |

1.0 |

25 |

60 |

115 |

10.1 |

6 |

| CC 10.210~10.305 |

1.0 |

25 |

60 |

115 |

10.2 |

6 |

| CC 10.310~10.405 |

1.0 |

25 |

60 |

115 |

10.3 |

6 |

| CC 10.410~10.505 |

1.0 |

25 |

60 |

115 |

10.4 |

6 |

| CC 10.510~10.605 |

1.0 |

25 |

60 |

115 |

10.5 |

6 |

| CC 10.610~10.705 |

1.0 |

25 |

60 |

115 |

10.6 |

6 |

| CC 10.710~10.805 |

1.0 |

25 |

60 |

115 |

10.7 |

6 |

| CC 10.810~10.905 |

1.0 |

25 |

60 |

115 |

10.8 |

6 |

| CC 10.910~11.005 |

1.0 |

25 |

60 |

115 |

10.9 |

6 |

| CC 11.010~11.105 |

1.0 |

25 |

70 |

130 |

11.0 |

6 |

| CC 11.110~11.205 |

1.0 |

25 |

70 |

130 |

11.1 |

6 |

| CC 11.210~11.305 |

1.0 |

25 |

70 |

130 |

11.2 |

6 |

| CC 11.310~11.405 |

1.0 |

25 |

70 |

130 |

11.3 |

6 |

| CC 11.410~11.505 |

1.0 |

25 |

70 |

130 |

11.4 |

6 |

| CC 11.510~11.605 |

1.0 |

25 |

70 |

130 |

11.5 |

6 |

| CC 11.610~11.705 |

1.0 |

25 |

70 |

130 |

11.6 |

6 |

| CC 11.710~11.805 |

1.0 |

25 |

70 |

130 |

11.7 |

6 |

| CC 11.810~11.905 |

1.0 |

25 |

70 |

130 |

11.8 |

6 |

| CC 11.910~12.005 |

1.0 |

25 |

70 |

130 |

11.9 |

6 |

| CC 12.010~12.100 |

1.0 |

25 |

70 |

130 |

12.0 |

6 |

参考切削条件

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

10~20 |

0.008~0.012 |

0.05 |

| 1 |

10~20 |

0.015~0.025 |

0.1 |

| 2 |

10~20 |

0.03~0.06 |

0.1 |

| 3 |

10~20 |

0.05~0.1 |

0.1 |

| 4 |

10~20 |

0.06~0.12 |

0.1 |

| 5 |

10~20 |

0.08~0.16 |

0.1 |

| 6 |

10~20 |

0.1~0.2 |

0.2 |

| 7 |

10~20 |

0.12~0.24 |

0.2 |

| 8 |

10~20 |

0.12~0.26 |

0.2 |

| 9 |

10~20 |

0.15~0.3 |

0.2 |

| 10 |

10~20 |

0.15~0.3 |

0.3 |

| 12 |

10~20 |

0.18~0.36 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

10~20 |

~0.005 |

0.05 |

| 1 |

10~20 |

~0.01 |

0.05 |

| 2 |

10~20 |

~0.017 |

0.08 |

| 3 |

10~20 |

~0.025 |

0.1 |

| 4 |

10~20 |

~0.03 |

0.1 |

| 5 |

10~20 |

~0.04 |

0.1 |

| 6 |

10~20 |

~0.05 |

0.1 |

| 7 |

10~20 |

~0.06 |

0.1 |

| 8 |

10~20 |

~0.06 |

0.1 |

| 9 |

10~20 |

~0.07 |

0.1 |

| 10 |

10~20 |

~0.07 |

0.2 |

| 12 |

10~20 |

~0.09 |

0.2 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

5~15 |

0.008~0.012 |

0.05 |

| 1 |

5~15 |

0.015~0.025 |

0.1 |

| 2 |

5~15 |

0.03~0.06 |

0.1 |

| 3 |

5~15 |

0.05~0.1 |

0.1 |

| 4 |

5~15 |

0.06~0.12 |

0.1 |

| 5 |

5~15 |

0.08~0.16 |

0.1 |

| 6 |

5~15 |

0.1~0.2 |

0.2 |

| 7 |

5~15 |

0.12~0.24 |

0.2 |

| 8 |

5~15 |

0.12~0.26 |

0.2 |

| 9 |

5~15 |

0.15~0.3 |

0.2 |

| 10 |

5~15 |

0.15~0.3 |

0.3 |

| 12 |

5~15 |

0.18~0.36 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

5~12 |

0.012~0.025 |

0.05 |

| 1 |

5~12 |

0.025~0.05 |

0.1 |

| 2 |

5~12 |

0.05~0.08 |

0.1 |

| 3 |

5~12 |

0.075~0.12 |

0.1 |

| 4 |

5~12 |

0.1~0.15 |

0.1 |

| 5 |

5~12 |

0.12~0.17 |

0.1 |

| 6 |

5~12 |

0.15~0.2 |

0.2 |

| 7 |

5~12 |

0.18~0.24 |

0.2 |

| 8 |

5~12 |

0.18~0.26 |

0.2 |

| 9 |

5~12 |

0.2~0.3 |

0.2 |

| 10 |

5~12 |

0.2~0.3 |

0.3 |

| 12 |

5~12 |

0.27~0.36 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

10~18 |

0.008~0.012 |

0.05 |

| 1 |

10~18 |

0.015~0.025 |

0.1 |

| 2 |

10~18 |

0.03~0.05 |

0.1 |

| 3 |

10~18 |

0.05~0.75 |

0.1 |

| 4 |

10~18 |

0.06~0.1 |

0.1 |

| 5 |

10~18 |

0.08~0.12 |

0.1 |

| 6 |

10~18 |

0.1~0.15 |

0.2 |

| 7 |

10~18 |

0.12~0.18 |

0.2 |

| 8 |

10~18 |

0.12~0.18 |

0.2 |

| 9 |

10~18 |

0.15~0.2 |

0.2 |

| 10 |

10~18 |

0.15~0.2 |

0.3 |

| 12 |

10~18 |

0.18~0.27 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

20~40 |

0.012~0.025 |

0.05 |

| 1 |

20~40 |

0.025~0.05 |

0.1 |

| 2 |

20~40 |

0.05~0.08 |

0.1 |

| 3 |

20~40 |

0.075~0.12 |

0.1 |

| 4 |

20~40 |

0.1~0.15 |

0.1 |

| 5 |

20~40 |

0.12~0.17 |

0.1 |

| 6 |

20~40 |

0.15~0.2 |

0.2 |

| 7 |

20~40 |

0.18~0.24 |

0.2 |

| 8 |

20~40 |

0.18~0.26 |

0.2 |

| 9 |

20~40 |

0.2~0.3 |

0.2 |

| 10 |

20~40 |

0.2~0.3 |

0.3 |

| 12 |

20~40 |

0.27~0.36 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

15~30 |

0.012~0.025 |

0.05 |

| 1 |

15~30 |

0.025~0.05 |

0.1 |

| 2 |

15~30 |

0.05~0.08 |

0.1 |

| 3 |

15~30 |

0.075~0.12 |

0.1 |

| 4 |

15~30 |

0.1~0.15 |

0.1 |

| 5 |

15~30 |

0.12~0.17 |

0.1 |

| 6 |

15~30 |

0.15~0.2 |

0.2 |

| 7 |

15~30 |

0.18~0.24 |

0.2 |

| 8 |

15~30 |

0.18~0.26 |

0.2 |

| 9 |

15~30 |

0.2~0.3 |

0.2 |

| 10 |

15~30 |

0.2~0.3 |

0.3 |

| 12 |

15~30 |

0.27~0.36 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

10~20 |

0.008~0.012 |

0.05 |

| 1 |

10~20 |

0.015~0.025 |

0.1 |

| 2 |

10~20 |

0.03~0.06 |

0.1 |

| 3 |

10~20 |

0.05~0.1 |

0.1 |

| 4 |

10~20 |

0.06~0.12 |

0.1 |

| 5 |

10~20 |

0.08~0.16 |

0.1 |

| 6 |

10~20 |

0.1~0.2 |

0.2 |

| 7 |

10~20 |

0.12~0.24 |

0.2 |

| 8 |

10~20 |

0.12~0.26 |

0.2 |

| 9 |

10~20 |

0.15~0.3 |

0.2 |

| 10 |

10~20 |

0.15~0.3 |

0.3 |

| 12 |

10~20 |

0.18~0.36 |

0.3 |

| 刃径DC(mm) |

切削速度Vc(m/min) |

送り量f(mm/rev) |

リーマ代(φmm) |

| 0.5 |

5~15 |

0.005~0.012 |

0.05 |

| 1 |

5~15 |

0.01~0.025 |

0.05 |

| 2 |

5~15 |

0.017~0.05 |

0.08 |

| 3 |

5~15 |

0.025~0.075 |

0.1 |

| 4 |

5~15 |

0.03~0.1 |

0.1 |

| 5 |

5~15 |

0.04~0.12 |

0.1 |

| 6 |

5~15 |

0.05~0.15 |

0.1 |

| 7 |

5~15 |

0.06~0.18 |

0.1 |

| 8 |

5~15 |

0.06~0.18 |

0.1 |

| 9 |

5~15 |

0.07~0.2 |

0.1 |

| 10 |

5~15 |

0.07~0.2 |

0.2 |

| 12 |

5~15 |

0.09~0.27 |

0.2 |