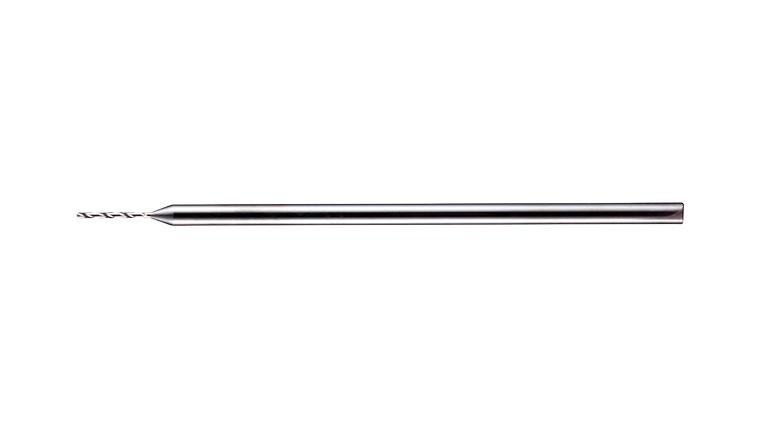

超硬リーマ

超硬リーマ Gシリーズ

CG○.○○○

- 幅広い被削材に対応し、安定した高精度加工を実現。

- 超硬素材の採用により、ハイスリーマと比べ、更なる高速·高能率加工が可能。

- Φ0.3から0.005mmとびの為、サイズに切れ間が無く、あらゆる要求穴公差に対応。

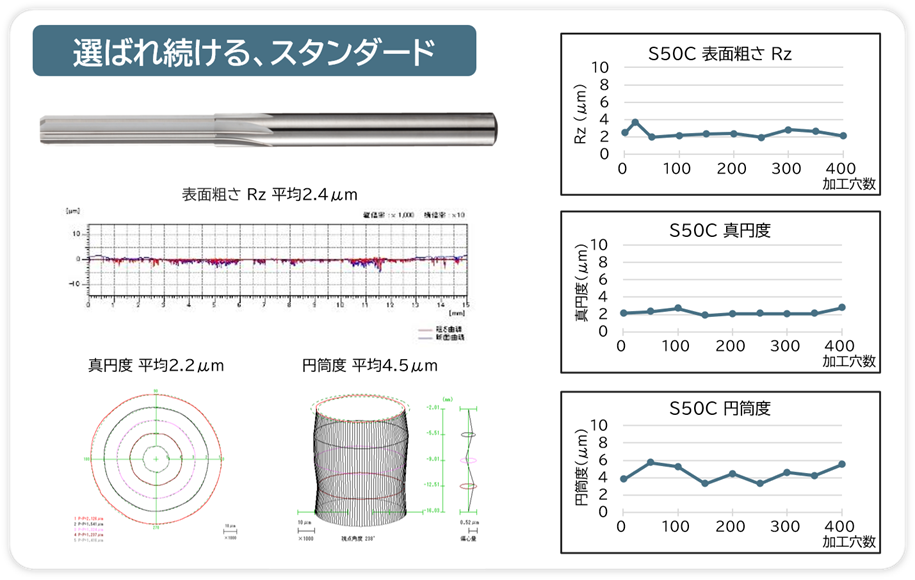

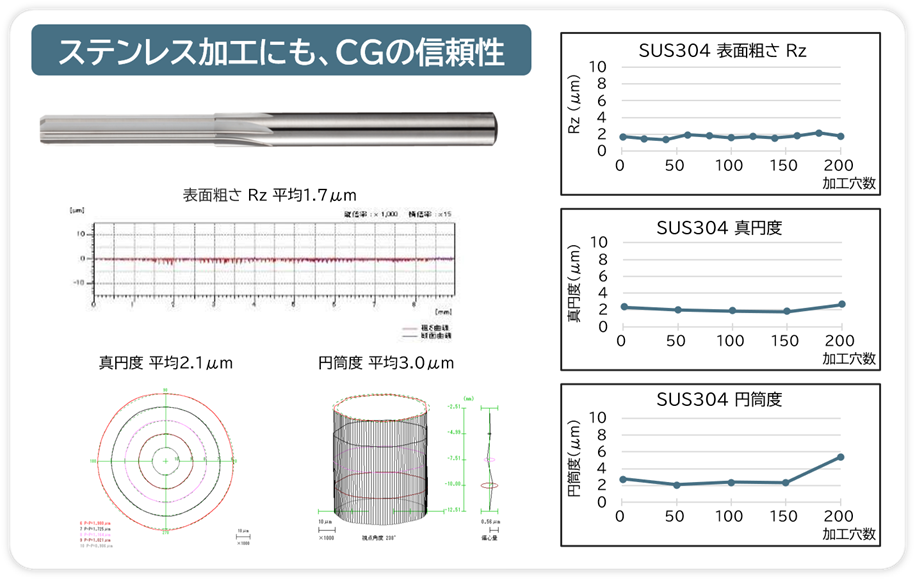

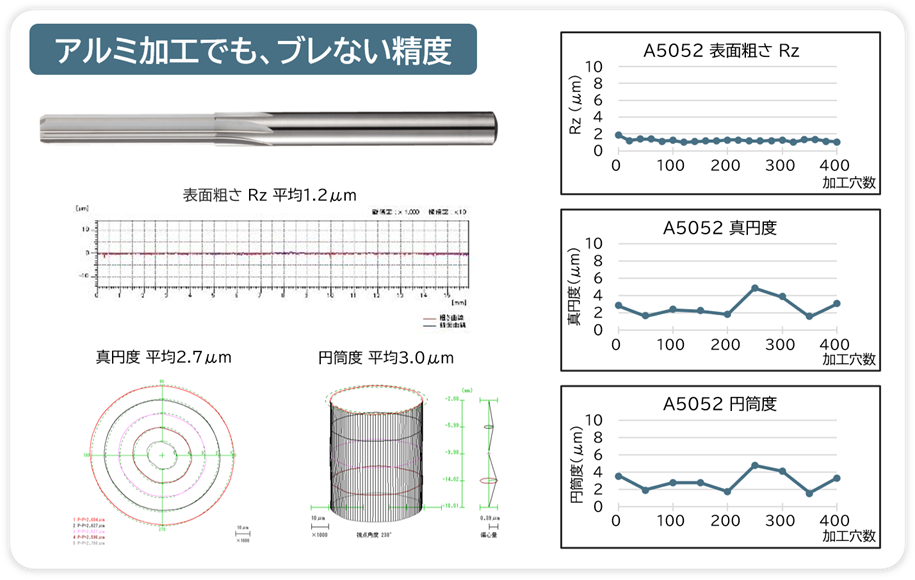

本製品の加工事例

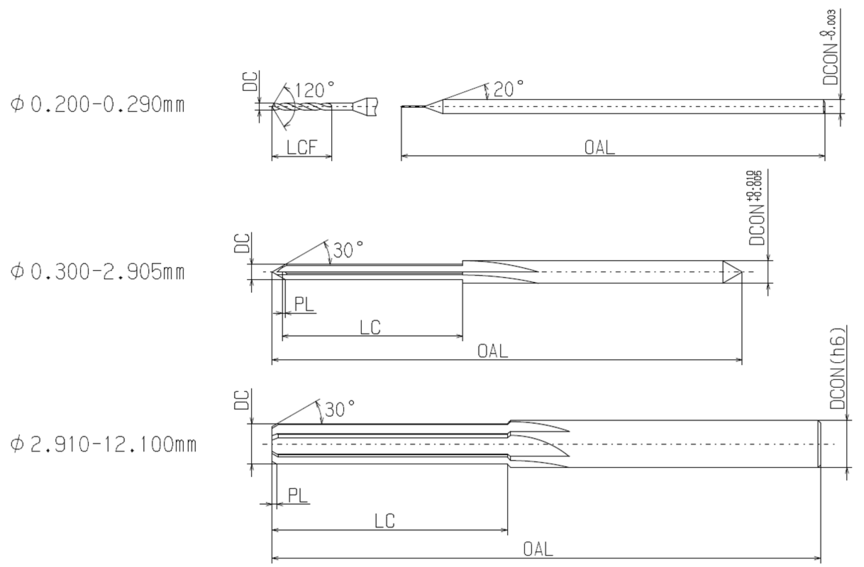

寸法表

| 型式・刃径DC | 溝長LCF | 全長OAL | シャンク径DCON | 刃数ZEFP |

|---|---|---|---|---|

|

CG 0.200~0.290

|

3 | 45 | 1.0 | 2 |

| 型式・刃径DC | 食付き長PL | 刃長LC | 全長OAL | シャンク径DCON | 刃数ZEFP |

|---|---|---|---|---|---|

| CG 0.300~0.405 | 0.1 | 4 | 50 | 1.0 | 4 |

| CG 0.410~0.505 | 0.1 | 5 | 50 | 1.0 | 4 |

| CG 0.510~0.605 | 0.1 | 6 | 50 | 1.0 | 4 |

| CG 0.610~0.705 | 0.1 | 10 | 50 | 1.0 | 4 |

| CG 0.710~1.005 | 0.2 | 12 | 50 | 1.0 | 4 |

| CG 1.010~1.305 | 0.2 | 15 | 50 | 1.5 | 4 |

| CG 1.310~1.505 | 0.3 | 16 | 50 | 1.5 | 4 |

| CG 1.510~2.005 | 0.4 | 18 | 50 | 2.0 | 4 |

| CG 2.010~2.505 | 0.5 | 20 | 50 | 2.5 | 4 |

| CG 2.510~2.905 ↑凸センタ |

0.5 | 20 | 50 | 3.0 | 4 |

| CG 2.910~3.005 ↓穴センタ |

0.5 | 27 | 60 | 3.0 | 4 |

| CG 3.010~3.505 | 0.5 | 27 | 60 | 3.5 | 4 |

| CG 3.510~4.005 | 0.5 | 27 | 60 | 4.0 | 4 |

| CG 4.010~4.505 | 0.5 | 30 | 70 | 4.5 | 6 |

| CG 4.510~5.005 | 0.5 | 30 | 70 | 5.0 | 6 |

| CG 5.010~5.505 | 0.8 | 30 | 80 | 5.5 | 6 |

| CG 5.510~6.005 | 0.8 | 30 | 80 | 6.0 | 6 |

| CG 6.010~7.005 | 0.8 | 35 | 80 | 7.0 | 6 |

| CG 7.010~8.005 | 0.8 | 35 | 80 | 8.0 | 6 |

| CG 8.010~9.005 | 1.0 | 40 | 90 | 9.0 | 6 |

| CG 9.010~10.005 | 1.0 | 40 | 90 | 10.0 | 6 |

| CG 10.010~11.005 | 1.0 | 40 | 90 | 11.0 | 6 |

| CG 11.010~12.100 | 1.0 | 45 | 90 | 12.0 | 6 |

参考切削条件

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 10~20 | 0.008~0.012 | 0.05 |

| 1 | 10~20 | 0.015~0.025 | 0.1 |

| 2 | 10~20 | 0.03~0.06 | 0.1 |

| 3 | 10~20 | 0.05~0.1 | 0.1 |

| 4 | 10~20 | 0.06~0.12 | 0.1 |

| 5 | 10~20 | 0.08~0.16 | 0.1 |

| 6 | 10~20 | 0.1~0.2 | 0.2 |

| 7 | 10~20 | 0.12~0.24 | 0.2 |

| 8 | 10~20 | 0.12~0.26 | 0.2 |

| 9 | 10~20 | 0.15~0.3 | 0.2 |

| 10 | 10~20 | 0.15~0.3 | 0.3 |

| 12 | 10~20 | 0.18~0.36 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 10~20 | ~0.005 | 0.05 |

| 1 | 10~20 | ~0.01 | 0.05 |

| 2 | 10~20 | ~0.017 | 0.08 |

| 3 | 10~20 | ~0.025 | 0.1 |

| 4 | 10~20 | ~0.03 | 0.1 |

| 5 | 10~20 | ~0.04 | 0.1 |

| 6 | 10~20 | ~0.05 | 0.1 |

| 7 | 10~20 | ~0.06 | 0.1 |

| 8 | 10~20 | ~0.06 | 0.1 |

| 9 | 10~20 | ~0.07 | 0.1 |

| 10 | 10~20 | ~0.07 | 0.2 |

| 12 | 10~20 | ~0.09 | 0.2 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 5~15 | 0.008~0.012 | 0.05 |

| 1 | 5~15 | 0.015~0.025 | 0.1 |

| 2 | 5~15 | 0.03~0.06 | 0.1 |

| 3 | 5~15 | 0.05~0.1 | 0.1 |

| 4 | 5~15 | 0.06~0.12 | 0.1 |

| 5 | 5~15 | 0.08~0.16 | 0.1 |

| 6 | 5~15 | 0.1~0.2 | 0.2 |

| 7 | 5~15 | 0.12~0.24 | 0.2 |

| 8 | 5~15 | 0.12~0.26 | 0.2 |

| 9 | 5~15 | 0.15~0.3 | 0.2 |

| 10 | 5~15 | 0.15~0.3 | 0.3 |

| 12 | 5~15 | 0.18~0.36 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 5~12 | 0.012~0.025 | 0.05 |

| 1 | 5~12 | 0.025~0.05 | 0.1 |

| 2 | 5~12 | 0.05~0.08 | 0.1 |

| 3 | 5~12 | 0.075~0.12 | 0.1 |

| 4 | 5~12 | 0.1~0.15 | 0.1 |

| 5 | 5~12 | 0.12~0.17 | 0.1 |

| 6 | 5~12 | 0.15~0.2 | 0.2 |

| 7 | 5~12 | 0.18~0.24 | 0.2 |

| 8 | 5~12 | 0.18~0.26 | 0.2 |

| 9 | 5~12 | 0.2~0.3 | 0.2 |

| 10 | 5~12 | 0.2~0.3 | 0.3 |

| 12 | 5~12 | 0.27~0.36 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 10~18 | 0.008~0.012 | 0.05 |

| 1 | 10~18 | 0.015~0.025 | 0.1 |

| 2 | 10~18 | 0.03~0.05 | 0.1 |

| 3 | 10~18 | 0.05~0.75 | 0.1 |

| 4 | 10~18 | 0.06~0.1 | 0.1 |

| 5 | 10~18 | 0.08~0.12 | 0.1 |

| 6 | 10~18 | 0.1~0.15 | 0.2 |

| 7 | 10~18 | 0.12~0.18 | 0.2 |

| 8 | 10~18 | 0.12~0.18 | 0.2 |

| 9 | 10~18 | 0.15~0.2 | 0.2 |

| 10 | 10~18 | 0.15~0.2 | 0.3 |

| 12 | 10~18 | 0.18~0.27 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 20~40 | 0.012~0.025 | 0.05 |

| 1 | 20~40 | 0.025~0.05 | 0.1 |

| 2 | 20~40 | 0.05~0.08 | 0.1 |

| 3 | 20~40 | 0.075~0.12 | 0.1 |

| 4 | 20~40 | 0.1~0.15 | 0.1 |

| 5 | 20~40 | 0.12~0.17 | 0.1 |

| 6 | 20~40 | 0.15~0.2 | 0.2 |

| 7 | 20~40 | 0.18~0.24 | 0.2 |

| 8 | 20~40 | 0.18~0.26 | 0.2 |

| 9 | 20~40 | 0.2~0.3 | 0.2 |

| 10 | 20~40 | 0.2~0.3 | 0.3 |

| 12 | 20~40 | 0.27~0.36 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 15~30 | 0.012~0.025 | 0.05 |

| 1 | 15~30 | 0.025~0.05 | 0.1 |

| 2 | 15~30 | 0.05~0.08 | 0.1 |

| 3 | 15~30 | 0.075~0.12 | 0.1 |

| 4 | 15~30 | 0.1~0.15 | 0.1 |

| 5 | 15~30 | 0.12~0.17 | 0.1 |

| 6 | 15~30 | 0.15~0.2 | 0.2 |

| 7 | 15~30 | 0.18~0.24 | 0.2 |

| 8 | 15~30 | 0.18~0.26 | 0.2 |

| 9 | 15~30 | 0.2~0.3 | 0.2 |

| 10 | 15~30 | 0.2~0.3 | 0.3 |

| 12 | 15~30 | 0.27~0.36 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 10~20 | 0.008~0.012 | 0.05 |

| 1 | 10~20 | 0.015~0.025 | 0.1 |

| 2 | 10~20 | 0.03~0.06 | 0.1 |

| 3 | 10~20 | 0.05~0.1 | 0.1 |

| 4 | 10~20 | 0.06~0.12 | 0.1 |

| 5 | 10~20 | 0.08~0.16 | 0.1 |

| 6 | 10~20 | 0.1~0.2 | 0.2 |

| 7 | 10~20 | 0.12~0.24 | 0.2 |

| 8 | 10~20 | 0.12~0.26 | 0.2 |

| 9 | 10~20 | 0.15~0.3 | 0.2 |

| 10 | 10~20 | 0.15~0.3 | 0.3 |

| 12 | 10~20 | 0.18~0.36 | 0.3 |

| 刃径DC(mm) | 切削速度Vc(m/min) | 送り量f(mm/rev) | リーマ代(φmm) |

|---|---|---|---|

| 0.5 | 5~15 | 0.005~0.012 | 0.05 |

| 1 | 5~15 | 0.01~0.025 | 0.05 |

| 2 | 5~15 | 0.017~0.05 | 0.08 |

| 3 | 5~15 | 0.025~0.075 | 0.1 |

| 4 | 5~15 | 0.03~0.1 | 0.1 |

| 5 | 5~15 | 0.04~0.12 | 0.1 |

| 6 | 5~15 | 0.05~0.15 | 0.1 |

| 7 | 5~15 | 0.06~0.18 | 0.1 |

| 8 | 5~15 | 0.06~0.18 | 0.1 |

| 9 | 5~15 | 0.07~0.2 | 0.1 |

| 10 | 5~15 | 0.07~0.2 | 0.2 |

| 12 | 5~15 | 0.09~0.27 | 0.2 |